If you’re a huge fan of Percy the Mars rover, you might be familiar with the power system that brings it to life.

The system — called a “Multi-mission Radioisotope Thermoelectric Generator” — is a thermoelectric device that converts heat from the natural radioactive decay of plutonium into electricity, powering Percy’s movement and its suite of scientific instruments on the Red Planet.

Despite its out-of-this-world application, the thermoelectric device is actually very desirable here on Earth. But the problem lies in its conversion efficiency. An efficiency of 4 – 5% works perfectly fine to power the Perseverance rover on Mars, but it’s not quite good enough to sustain applications on Earth. Current materials are also just too pricey for widespread use.

But scientists from Northwestern University and Seoul National University seem to have cracked the code, which could pave the way for a new generation of greener car engines, industrial furnaces and other energy-consuming devices.

Breakthrough material for thermoelectric devices.

Published in the journal Nature Materials, the study demonstrated a high-performing thermoelectric material in a practical and cost-effective form that can be used in device development.

Led by Dr In Chung from Seoul National University and Professor Mercouri Kanatzidis from Northwestern University, the team of researchers cooked up a new material called polycrystalline tin selenide, which can be made from readily available materials at a low cost.

They’ve also meticulously pin-pointed and overcame the main hurdle affecting the performance of the material — oxygen layers coating the individual grains of polycrystalline tin selenide. The “oxygen skin” increases the heat conductivity between grains, dramatically reducing the thermoelectric efficiency.

Removing the oxygen layer results in pristine polycrystalline tin selenide, which lowers the thermal conductivity and increases the ZT score. In other words, it’s a major breakthrough.

But wait, what’s a “ZT score”? And is mine high?

The ZT score.

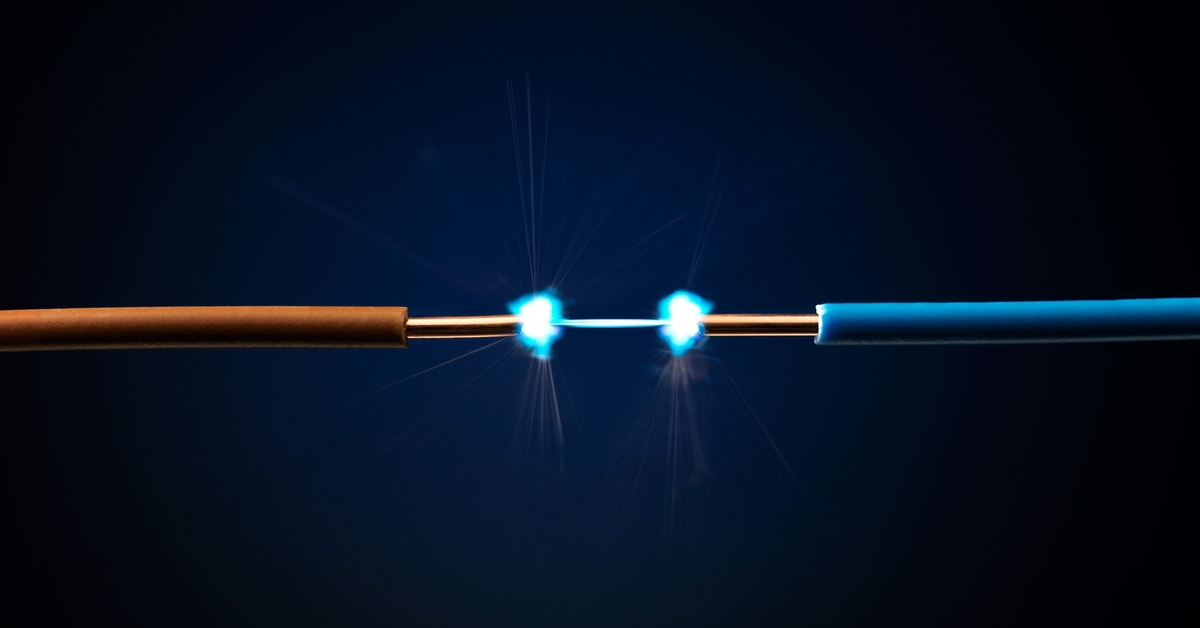

Thermoelectrics are semiconductor devices that are placed on hot surfaces, such as the engines of gas-powered vehicles. That gives the devices a hot side and a cool side. The devices work by harnessing the heat energy to push electrical charges from one side to the other. If the intrinsic material of the device allows the hot side to warm up the cool side, electricity stops flowing through it.

The ZT score, also known as the figure of merit, measures how well a device prevents that from happening, as well as its ability to conduct electrons. In essence, researchers strive to get the score as high as possible. Dr Chung’s team managed to get a ZT score of 3.1 for their new material, marking a 41% increase in efficiency compared to the single-crystal tin selenide.

Wide-ranging applications.

Moving forward, the research team is now taking their polycrystalline tin selenide to a higher level by spiking it with bromine atoms so that they become an “n-type” material. As opposed to “p-type” materials that conduct positive charges, “n-type” materials conduct negative charges, which are both paired to make thermoelectric generators workable.

Prospective areas of application of such devices are wide-ranging. In the automotive industry, the devices could be installed on vehicle exhaust pipes as they emit a significant amount of potential energy (a.k.a. heat) from gasoline. In the heavy manufacturing industry, they could be installed in refinery furnaces to scavenge excess energy. They can also be used in large combustion engines that operate for an extended period such as those on large ships and tankers.

With over 50% of global energy input as waste heat, we will need an ingenious way to capture as much of it as possible. And these thermoelectric devices can potentially open the door to that possibility.