In the near future, you’d be able to walk into a Japanese restaurant and order: “One medium-rare 3D printed Wagyu, arigatou gozaimasu!”

Wait what?!

You might have heard of 3D printed Lego bricks or cellphone cases or pasta, but have you come across 3D printed beef?

Researchers from Osaka University are beefing up their research in food engineering to make serving 3D printed beef a reality. They’ve successfully 3D printed a cut of Wagyu beef — meat from the eponymous Japanese cattle, which is famous for its marbling and exorbitant costs. (High-grade Wagyu costs $200 for about 500 grams)

How on Earth is Wagyu printed?

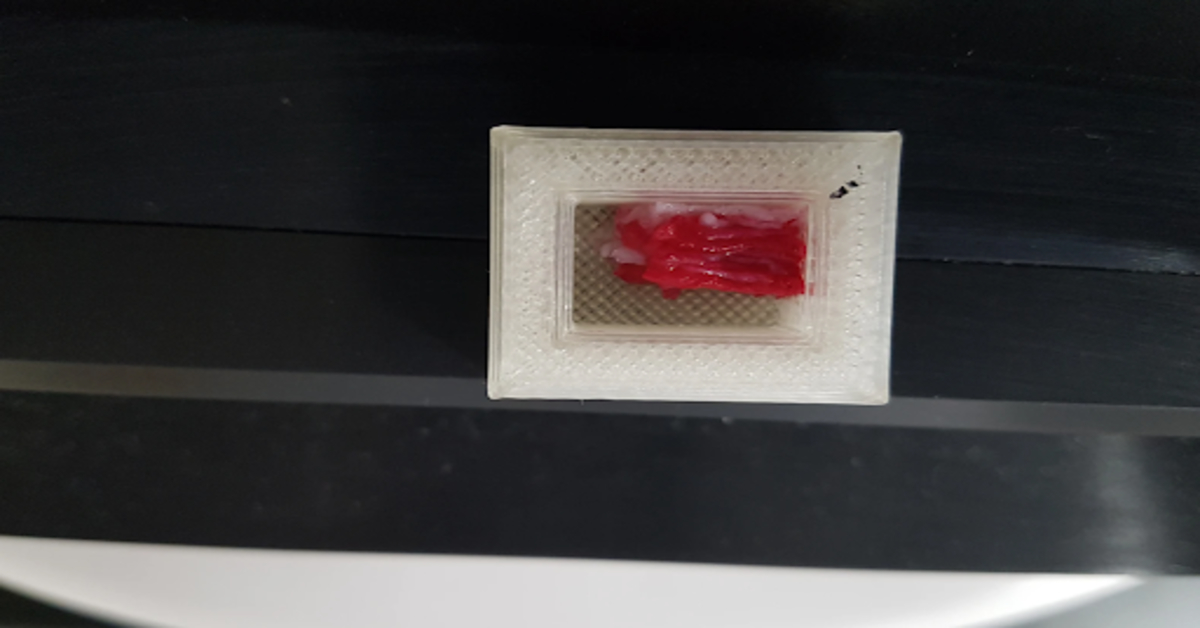

Published in the journal Nature Communications, the Japanese researchers first isolated and grew two different types of cells from a Wagyu cow’s cheeks. Satellite cells, biological precursors for muscle growth, were used to form the muscle, i.e. the red parts of the steak. Then, adipose stem cells were extracted from the cow’s fats and made into the steak’s veins and fat marbles.

Now here comes the challenge. The research team had to reconstitute the Wagyu’s signature intramuscular fat content, giving it that fantastic marbling, or as the Japanese call it, sashi.

After extraction, the researchers combined the grown cells with collagen-based artificial tendon tissues, making rolls of Wagyu beef fibre through a process called 3D bioprinting. Lastly, like piecing together an intricate puzzle, they assembled the rolls of fibre to mimic the histological structures of actual Wagyu steaks.

A potential alternative to livestock.

The researchers hope that this accurate and highly-controlled 3D printing method can improve lab-grown meat texture, as previous experiments involving cultured meats have grown mostly undefined and unstructured cuts. In theory, this customisable meat printing technique would also offer customers a lot of flexibility in having as much fat or lean meat as they want in their steak. If you already had a lot of oily food during the day, then order a 3D printed Wagyu with less fat!

It’s also an appealing future option for those looking to reduce their reliance on livestock, which currently contribute to roughly 40% of the annual methane budget.

But the mass production of 3D printed steak is still a faraway goal. The researchers’ laboratory creation, albeit only 5 millimetres in diameter and 10 millimetres in length, already cost them about $900 to make!

And no one has tasted the product yet — more studies are still required before any human being is allowed to cook and eat it.

So what do you think — would you eat 3D printed Wagyu beef or do you think it’s a gastronomical misteak?