If data is the new oil, hydrogen could be the new (natural) gas. It could play a central role in tomorrow’s low-carbon energy system, and a sustainable hydrogen economy could potentially turn hard-to-abate sectors, such as shipping, aviation, agriculture, transportation and steel, into a thing of the past.

Hydrogen can be produced from various primary energy sources and by various technical processes. Some of the most common processes involve splitting water into hydrogen and oxygen using an electrolyser.

If renewable energy such as solar power is used, the electrolyser produces green hydrogen, which emits little to no greenhouse gases during the process. But some researchers are hoping to use direct sunlight to split water into hydrogen. And supercomputers play an important role in identifying materials to enable this process, in an effort to economise a crucial part of the hydrogen fuel production pipeline.

Splitting water into hydrogen with sunlight.

In a process called photocatalysis, water can be separated into hydrogen and oxygen in the presence of certain catalytic materials. But searching for such materials is akin to looking for a needle in a haystack. While Thomas Edison looked at just about every material under the sun until he found the right material for the light bulb, an international team of researchers turned to supercomputers for help.

Published in Energy & Environmental Science, the researchers reported a type of computational approach called “high-throughput materials screening” to narrow a list of more than 70,000 different compounds down to six promising candidates that can be used as photocatalysts for solar hydrogen production.

The compounds were obtained from the Materials Project database, an online open-access repository of known and predicted materials. Before the computational screening process, the team developed an algorithm to sniff out potential materials with properties that would make them great photocatalytic candidates for the hydrogen production process. For instance, the algorithm could predict the ideal energy range, or the band gap, of various materials for which they absorb sunlight. Not just that, the candidates also need to have perfect chemical stability – so that they don’t decompose in water – and of course, the ability to split water into hydrogen and oxygen without any external supplementation other than sunlight.

Turbocharging materials research with high-performance computing.

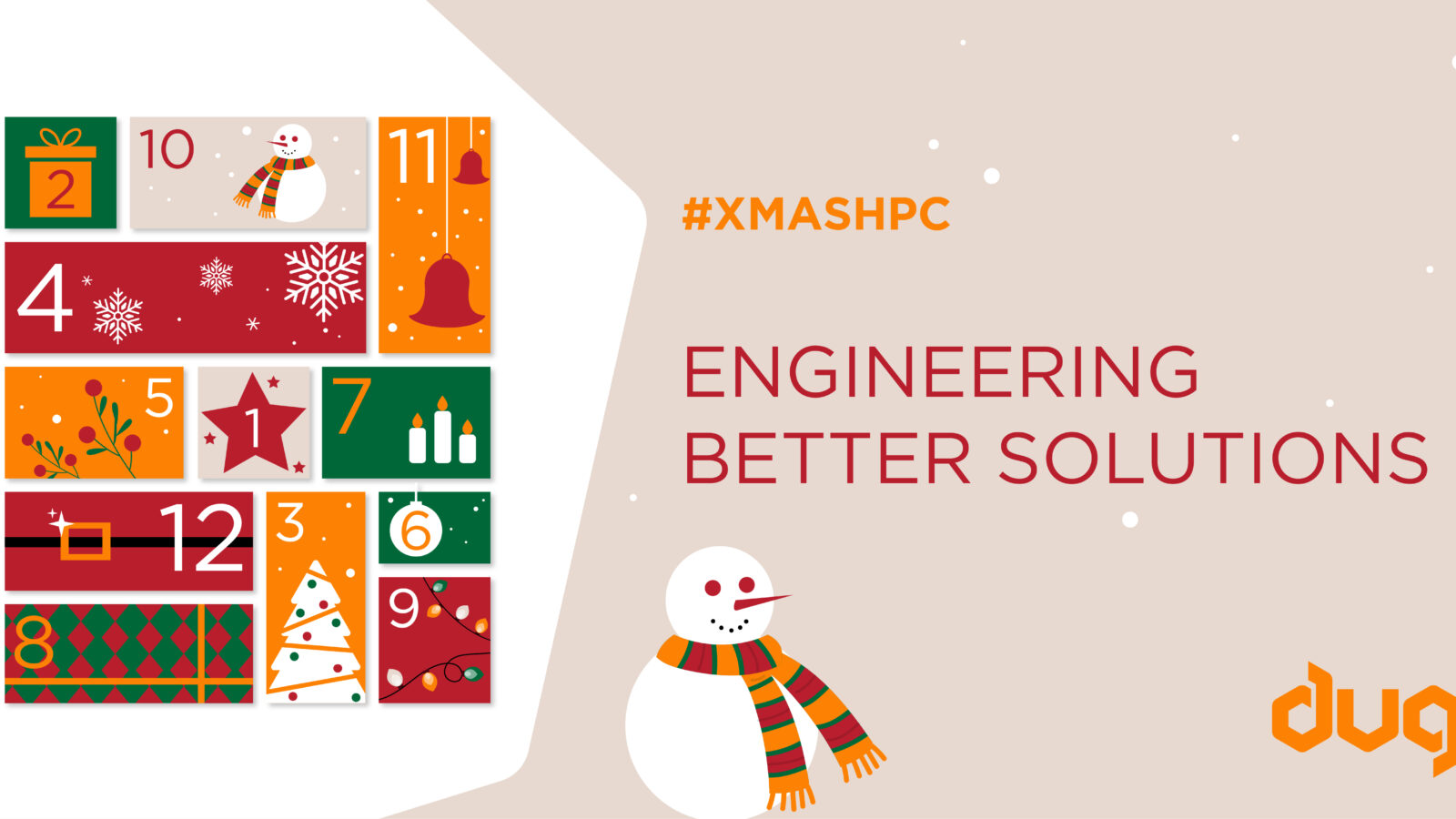

Run on The Pennsylvania State University’s own high-performance computing (HPC) infrastructure, the integrated computational-experimental workflow could greatly turbocharge the discovery of efficient materials not just for photocatalytic applications but also for a panoply of other vital chemical processes underpinning the world’s green economy.

But of course, the researchers still need to perform laboratory experiments to validate the efficacy of the photocatalysts – the supercomputers merely recommend what materials will be the most promising! Nevertheless, this computationally driven and data-intensive method could represent a revolution in experimental efficiency over the arduous and draining trial-and-error approach.

From hunting for innovative methods to degrade toxic chemicals, to uncovering the secret of the cosmos and brewing that perfect mug of frosty beer, the enormous and complicated world of research has been enhanced and disentangled in a multitude of facets since the advent of HPC. Now, scientists are even using silicon to replace silicon!

With the dawn of exascale computing right around the corner, advanced HPC offers a ray of hope in accelerating humanity’s efforts to curb greenhouse gas emissions, enabling the energy transition and advancement of clean technologies via digitalisation.